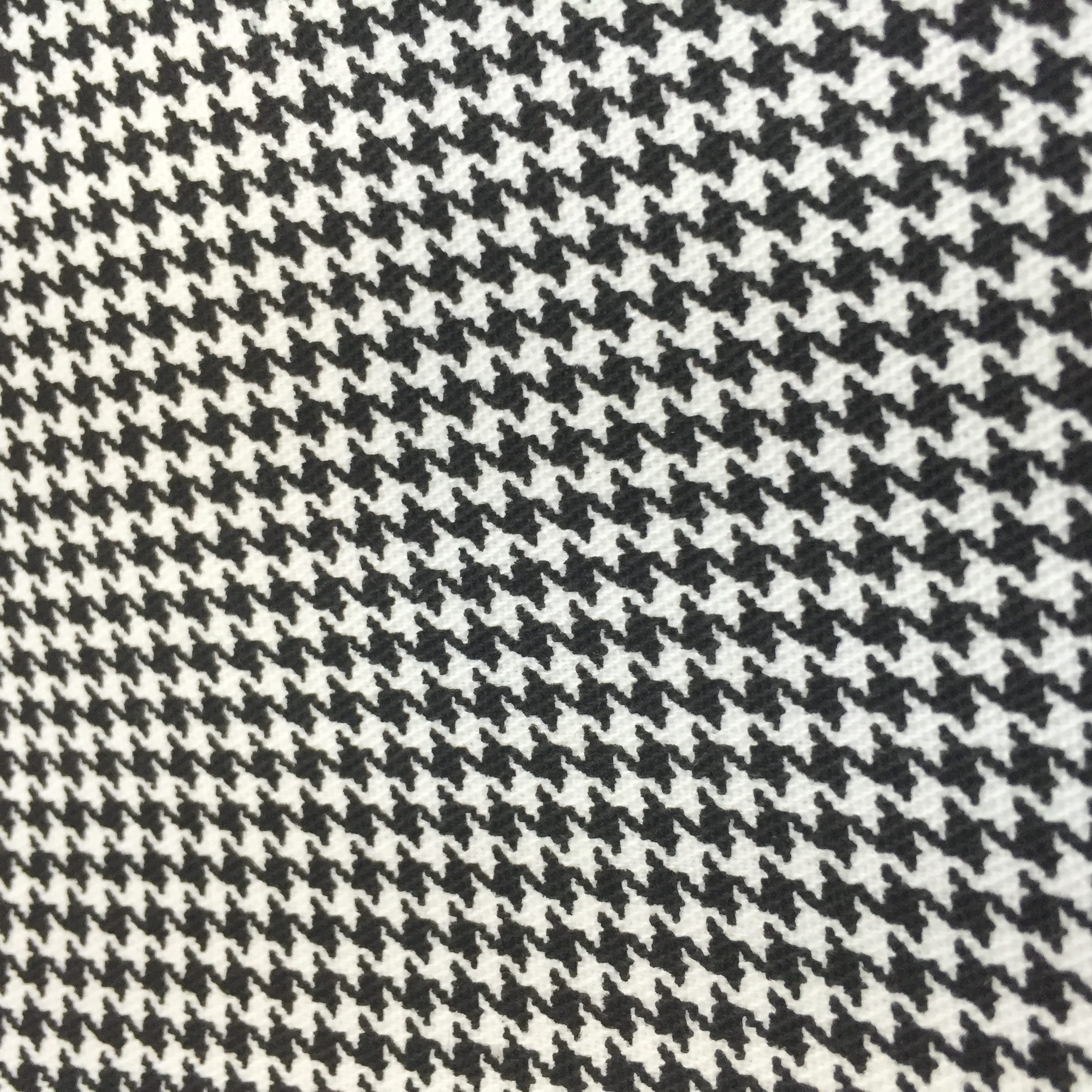

People purchase fabric for countless reason; look, feel, color, print and/or design, but Schott Textiles realizes that it is crucial to match the fabric to the intended end use and customer. And while stylish fabrics are often in demand, natural fabrics and the basic color palette including black & white are still the work horse of the wholesale industrial textile industry.

Schott Textiles’ knowledge & practical experience is important when customers need dyed fabrics. Knowing the important variables & demands of the end product can make the difference in a satisfied customer or not. Schott Textiles can help you sort through all these variables to find the right fabric for the end use, casual trial and error can be an expensive and unnecessary approach when working with dyed fabric.

Schott Textiles works with dye plants both domestically and overseas. Understanding the the capabilities of these dye plants and having long standing relationships is vital to sourcing the right materials in terms of quality and economic value.

All greige fabrics can be dyed, bleached or printed, but not all fabric qualities are worth the time & expense of further processing. Better quality yarns & modern weaving are the starting point for quality fabrics.